Ergonomic Redesign for Traditional Coppersmiths in Pune :

A UX Approach to Enhancing Artisanal Workspaces

Purpose

Problem Overview

The traditional coppersmiths of Tambat Ali, Pune, endure severe physical strain from outdated, uncomfortable workstations, putting them at risk for long-term health issues, particularly musculoskeletal disorders.This not only affects their well-being but also threatens the continuation of their craft.

Purpose

My Role

UX Researcher & Designer – field research, ergonomic evaluation, conceptual ideation, prototyping, and testing.

This was a collaborative group project with four team members: Shreya Sinha, Nishad Ghodke, Aarohi Singhal, and Swarali Natekar.

Duration

6 Weeks

Tools & Methods

REBA, WERA, Field Observations, Ethnographic Research, Prototyping, CAD

Challenge

Traditional coppersmiths in Pune face serious ergonomic challenges due to outdated workstations, leading to health risks such as chronic back pain, tendinitis, and vibration-related disorders. Generational knowledge has not translated into improved working conditions, impacting both their health and productivity. Addressing these issues is vital for their well-being and the preservation of their craft.

Problem

“Our backs hurt, our fingers go numb, but we have no choice — this is how it has always been done.” — Artisan at Tambat Ali

Design Process

Research & Discovery

Understanding the Problem

Field Research

User Interviews

REBA (Rapid Entire Body Assessment) and WERA (Workplace Ergonomic Risk Assessment)

Define

Problem Analysis

User Personas

Design Requirements

Ideate

Brainstorming Solutions

Low-fidelity Prototypes

Concept Testing

Design

Prototype and Evaluate

Research

Methods Used

Field Observations in active workshops

Interviews with 10+ artisans

Ergonomic Tools

REBA: Avg Score = 10 (High Risk)

WERA: Avg Score = 42 (Requires Change)

Key Pain Points

Prolonged static postures

Vibration from hammering

Lack of back/knee support

Awkward seating ("Khod")

Noise, lighting, ventilation hazards

Cultural Insight

The "Khod" is not just a seat—it's tradition. Any design had to preserve this emotional connection.

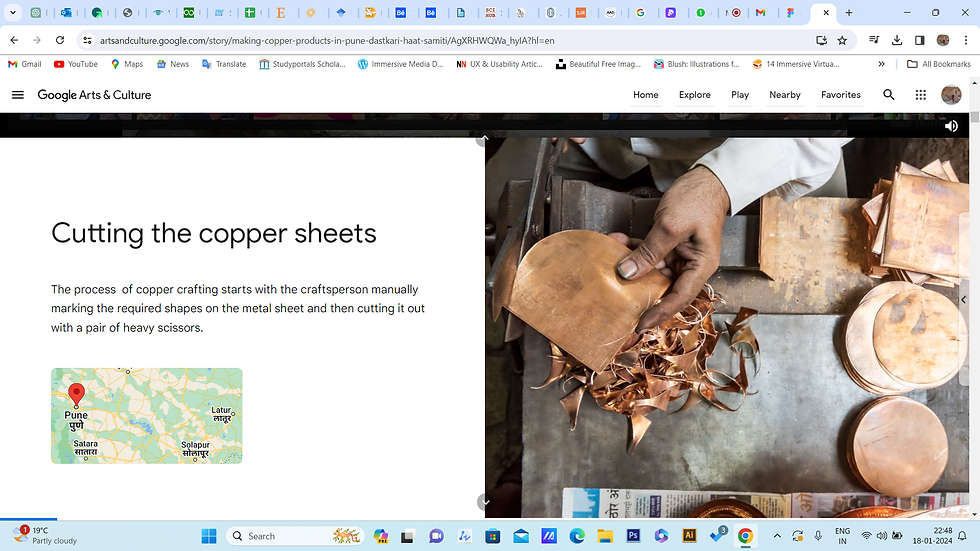

Process of making copper vessel

Katarkaam - copper sheets are cut into the desired shapes for the specific vessel.

Jodkam and Vijavne- Joining and Brazing forms into components

Jodkam and Vijavne- Joining and Brazing forms into components

Matharkam- Hammering the surfaces. Art of beating copper vessel to make it strong. It also gives a beautiful texture to the product.

Jadavkam - Buffing and polishing. Accessorizing the components.

Physical Model

Main Entry

Markham/hammering

Dye cast machine

Markham

Storage

Storage

Storage

Entry

Buffing machine

2.5 m

4 m

INSIGHTS

Space Constraints

Postural Discomfort

Noise and Vibration Hazards

Inadequate Lighting

Inadequate Ventilation

Artifact Model

Seat used by artisans

Hammering tools used in matharkaam

Khod(wooden seat)

Kharvai (Iron bar anvil)

Different cross-sections of kharvai, depending upon the vessel’s curve

11 cm

3 cm

17 cm

15 cm

15 cm

4.5 cm

110-140cm

11 cm

5.5 cm

Types

44 cm

67 cm

9 cm

21 cm

Insights From Site study

Temperature Extremes- Heat from copper shaping and polishing can lead to thermal stress.

Noise Exposure: Loud hammering sounds pose risks of hearing issues over time.

Vibration Exposure: Prolonged use of vibrating tools, like hammers, can cause discomfort.

Inadequate Hand Protection: Misuse of gloves when handling sharp materials increases the risk of cuts. Thick or ill-fitting gloves hinder the ability to manipulate small copper pieces.

Chemical exposure: Contact with chemicals used in metal finishing can cause skin irritation and respiratory issues.

Improper lighting: Inadequate workstation lighting can strain eyes and impact craftsmanship quality.

Awkward postures: Lack of suitable seating for detailed tasks for prolonged periods can cause fatigue

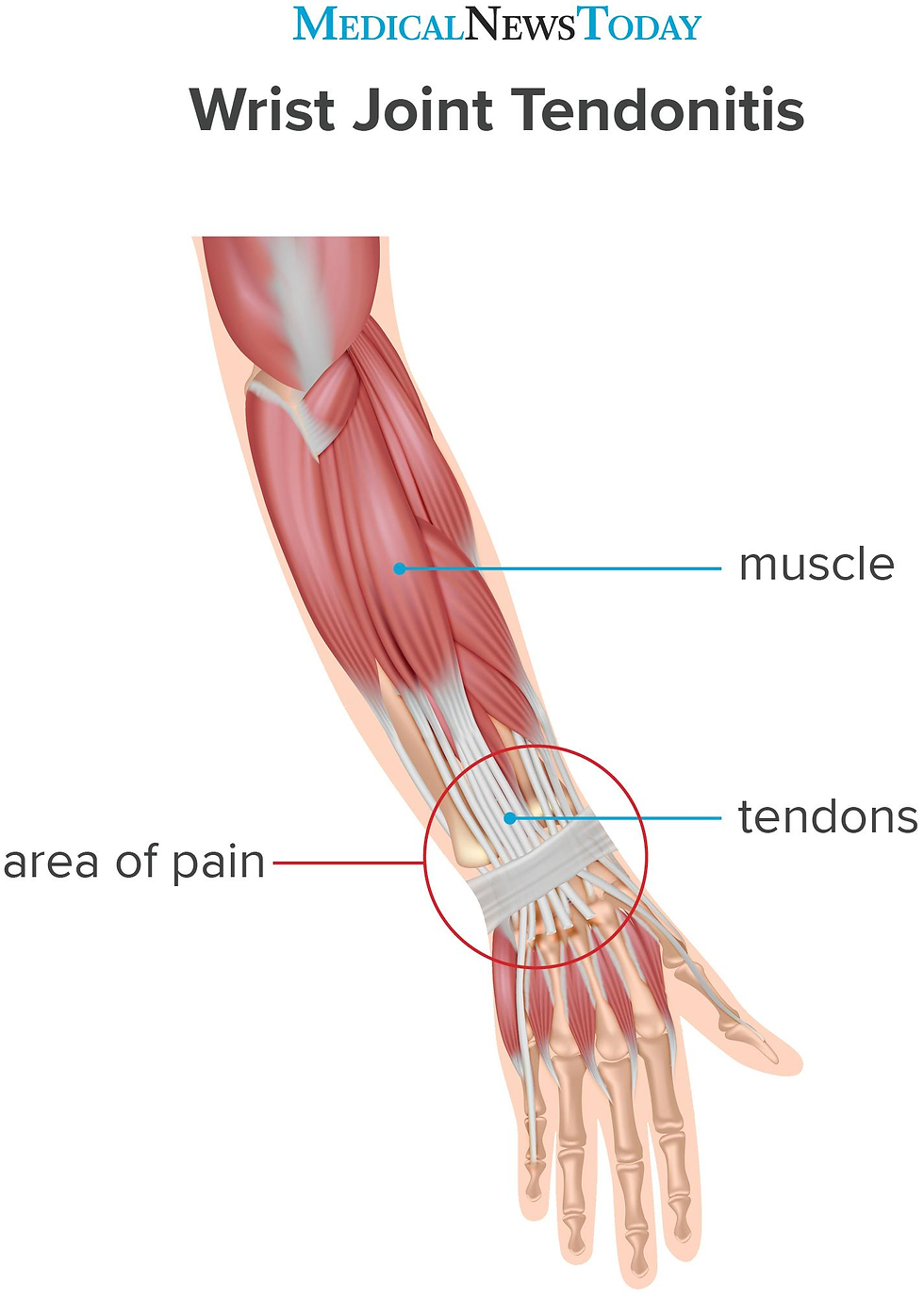

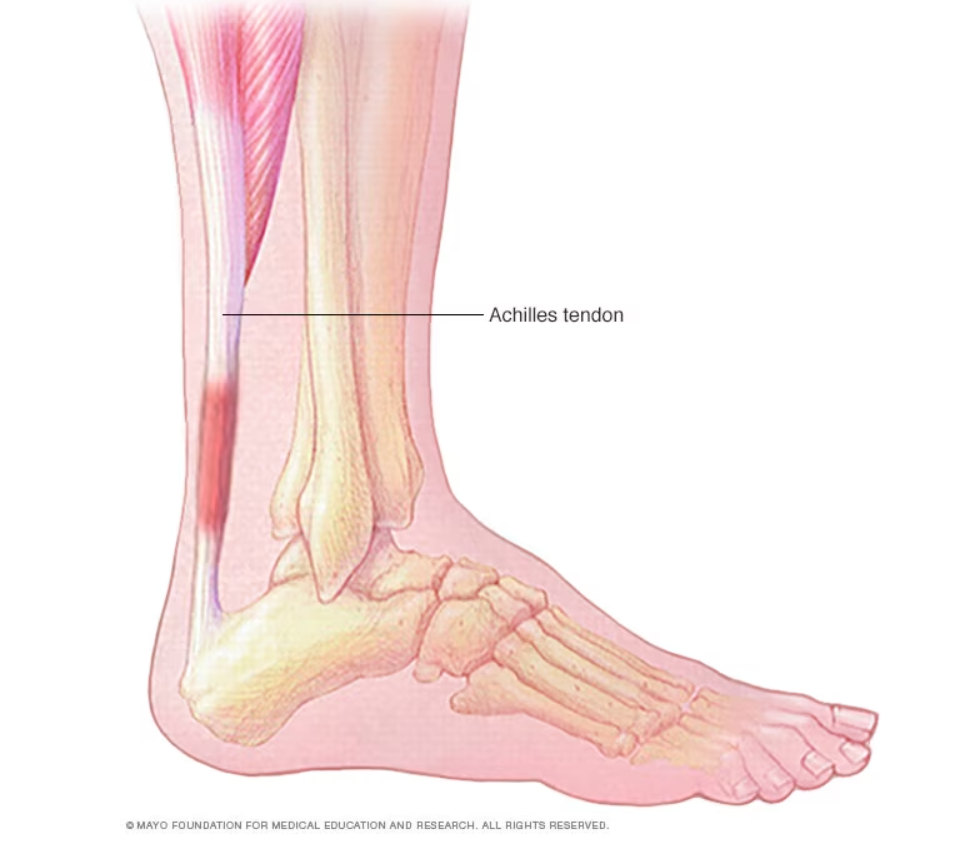

CTS

TENDINITIS

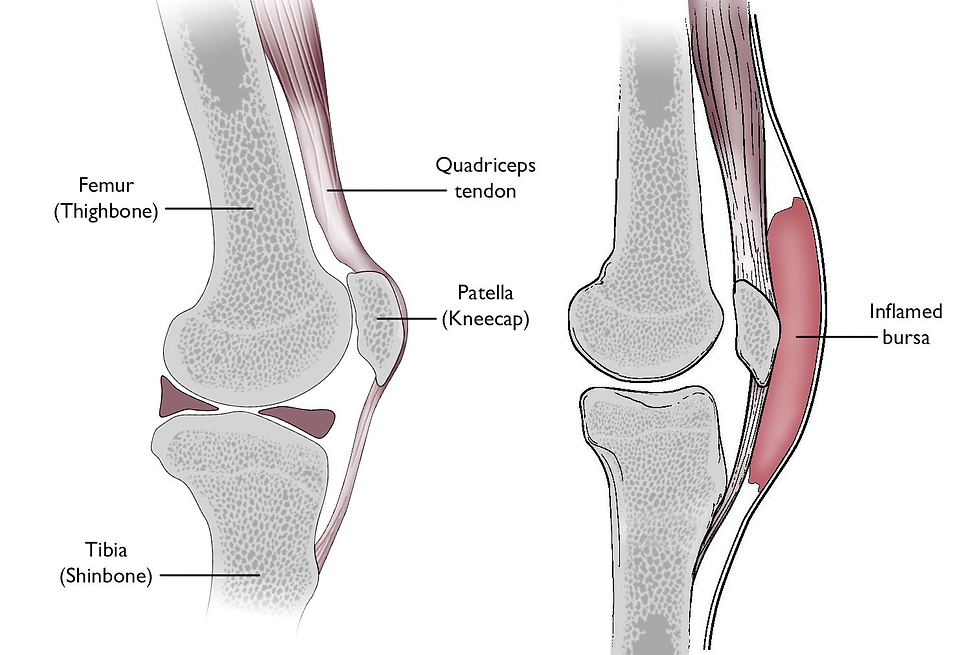

3.Pre Patellar Bursitis

LOWER BACK PAIN

ACHILLES TENDINITIS

HAVS

TRIGGER FINGER/ THUMB

EPICONDYLITIS

MSD (Musculoskeletal Disorder) SYMPTOMS IN COPPERSMITHS

Design Directions

Respect traditional workflows

Easy to produce and maintain locally

Maintain workspace compatibility

Integrate modern ergonomic support

Ideation & Concept Development

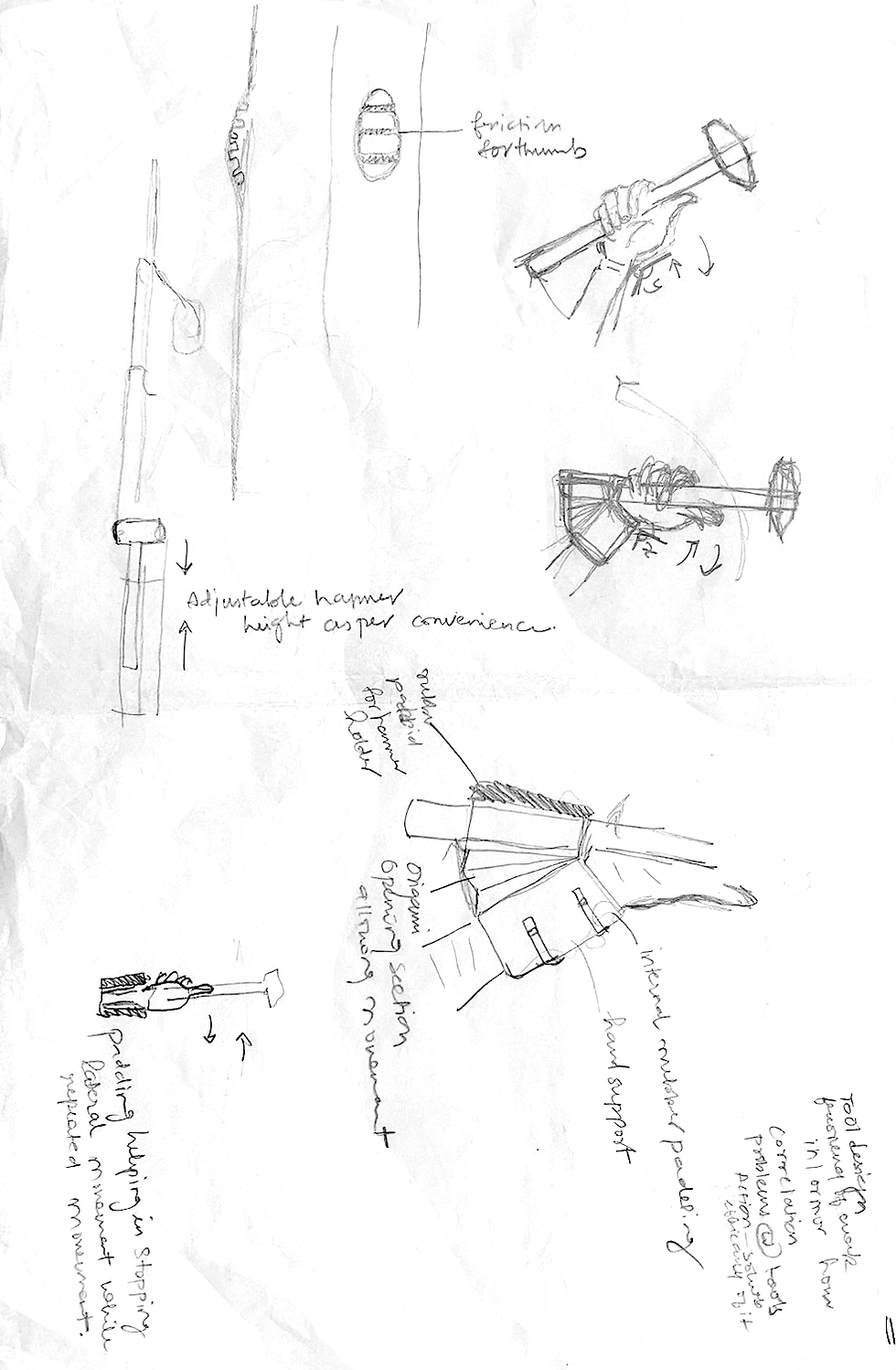

Solution 4- Tool Design

Solution 1- Work desk member

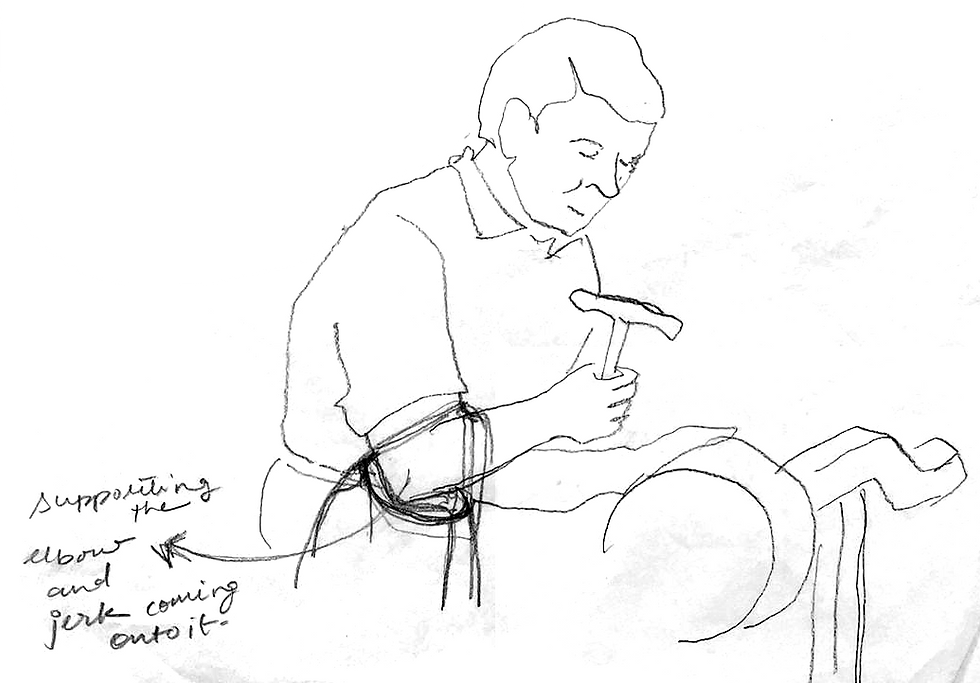

Solution 2- Elbow support

Awkward position of hands

There can be pain in the hands, if we increase the tool height

Material and Making cost high

PROBLEMS IDENTIFIED

Does not solve back and neck pain problem

Not economic for user

Adjustability is low

Material and Making cost high

PROBLEMS IDENTIFIED

minimize strain on the hands, wrists, and arms

better control and stability

higher productivity and better quality craftsmanship.

Expensive for user

may feel uncomfortable to use new tool

Tool design will not solve the back and neck pain

Pros

Cons

Solution 3- Wrist band

Seat

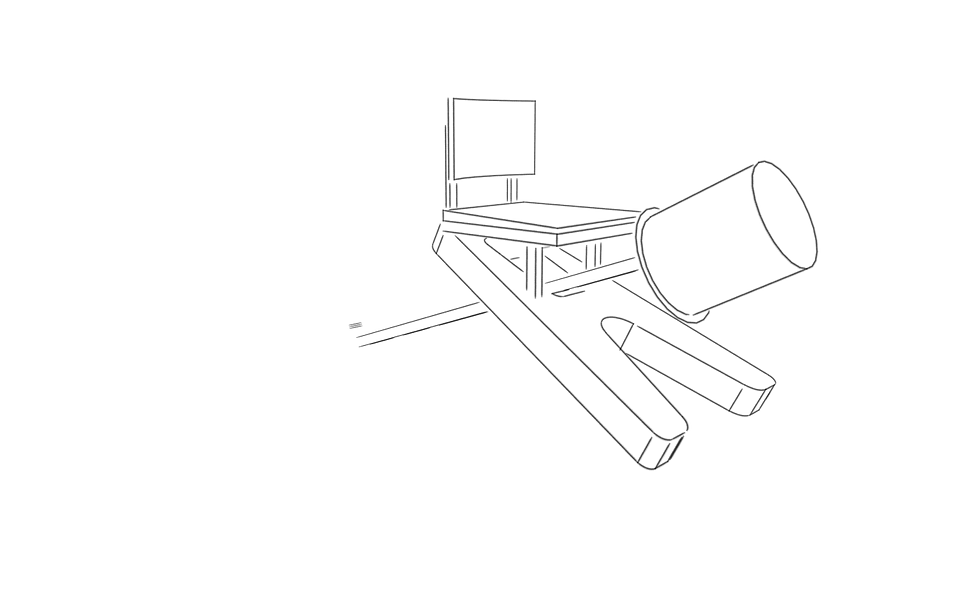

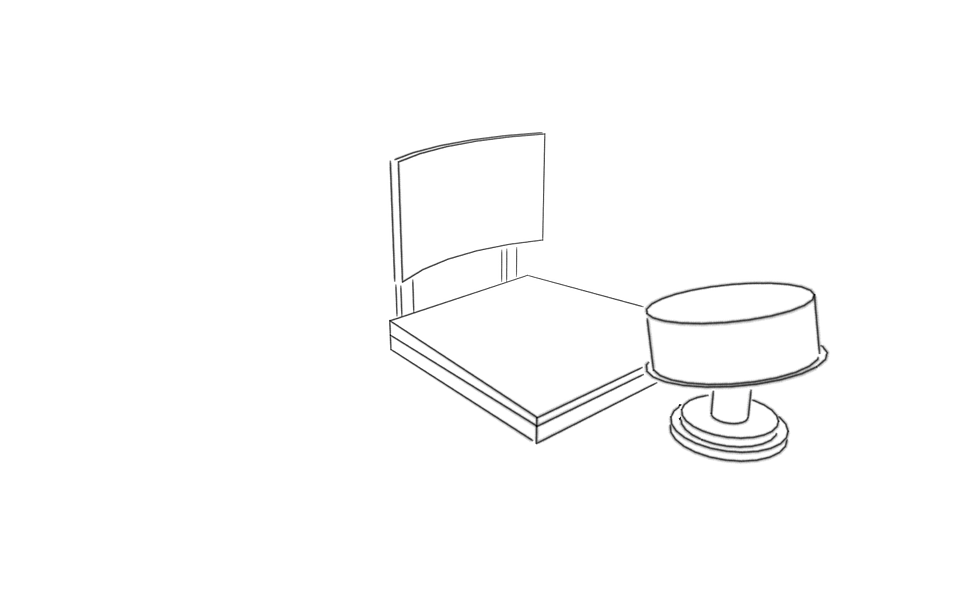

PRODUCT: SEAT DESIGN - Initial Concept 1

Cons

Pros

Not economic for user

Adjustability is low

Material and Making cost high

Huge as per workspace

Does not include all user type(size)

superior comfort

optimal support to the back, hips, and thighs

durable and resilient

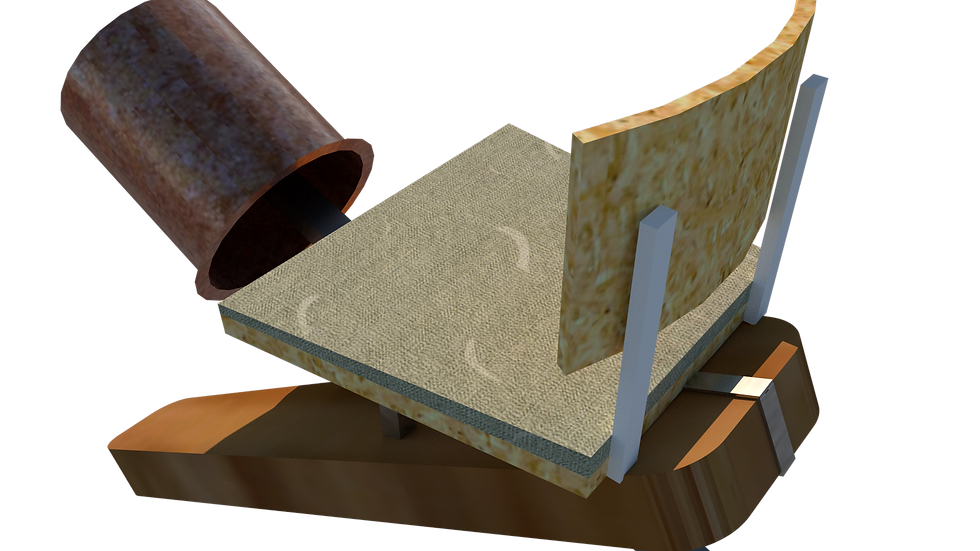

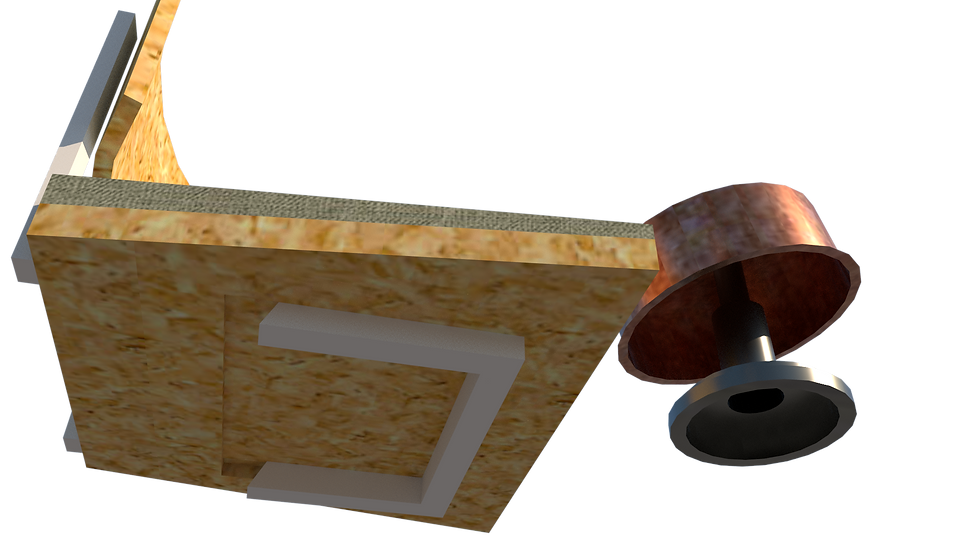

Final Design

The final seat design for coppersmiths enhances the traditional seat by adding features for better comfort and support while preserving its original style. It blends tradition with modern ergonomic improvements, providing a more comfortable and adaptable solution to address health concerns and improve working conditions.

The seat is designed to sit on khod as well as on floor for all types of coppersmith work

The angled support on bottom helps the seat sit firmly on the angled khod piece.

Iron rods stand behind to rest the back rest which will take the constant thrust felt while hammering`

Iron rods stand behind to rest the back rest which will take the constant thrust felt while hammering`

Foldable bottom support to be able to use the seat on ground

Final Product

Future Scope for Ergonomic Design:

Key Learnings & Reflections

User-Centered Design: Direct interaction with the artisans highlighted the importance of immersing oneself in the users' environment to uncover real pain points. This approach ensured our solutions were not only practical but also culturally sensitive.

Balancing Tradition and Innovation: Designing ergonomically while preserving traditional craftsmanship was a challenge. This project taught me how to blend modern ergonomic solutions without disrupting the artisans' time-honored methods.

Data-Driven Decisions: Utilizing tools like REBA and WERA helped back our design choices with measurable data, and how it impacs the artisans’ health and productivity.

Empathy in Design: Collaborating closely with the coppersmiths reinforced the importance of empathy in the design process. Their insights were instrumental in refining the final solution.

Adjustable Features

Material Upgrades

Enhanced Durability

Incorporating Sustainable Materials